Language

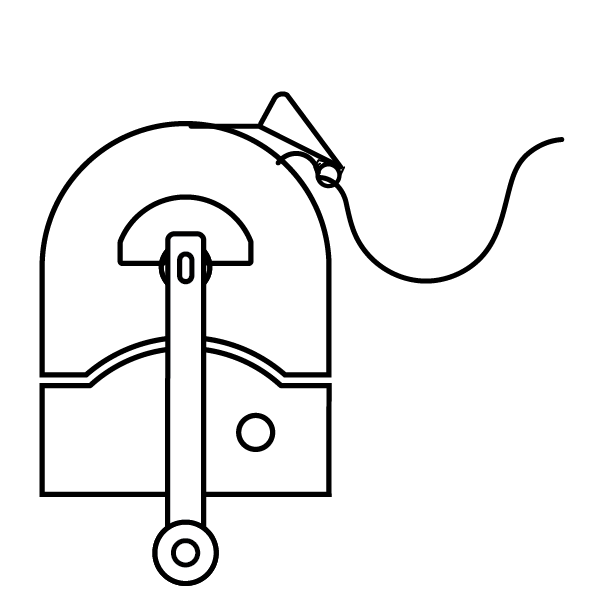

Treuil TS3000

Ref.:

PF703000

€437.35

incl. vat

In stock

Treuil de sécurité Goliath à sangle (incluse)pour remorque porte-bateau.

- Capacité : bateau de 3000kg

- Déroulement libre de la sangle hors charge

- Sécurité automatique (breveté)

Ref.origine: 954903

More Details

- Capacité : bateau de 3000kg

- Déroulement libre de la sangle hors charge

- Sécurité automatique (breveté)

Ref.origine: 954903

-

22.38

-

2 vitesses Effort <50%

-

Sangle et crochet inclus

-

Norme Européenne EN13157-A1

-

Manivelle amovible

-

Déroulage libre de sangle

GOLIATH has been designing and making, for more than 30 years, winches that are used in a great number of industries.

The manual winch is a safety device governed by strict technical rules and whose design is framed by the European standard EN13157 A1.

Here are some criteria to be taken into account to determine the right winch.

Lifting concept

According to the European standard EN13151 A1, a lifting application is characterised by the lifting of a load in connection with a vertical and/or horizontal movement. Thus, towing a car on a trailer, for example, is a lifting operation.

The winch associated with this operation must therefore imperatively be compliant with the standard EN13157 A1 to be EC marked. It must in particular have a permanent safety brake when loaded (as the range of ratchet winches does not have a self-braking system, it is therefore not suitable for lifting applications). This device is crucial to ensure your safety and the compliance of your facilities. For more information

The winch safety brake makes it possible to hold the load when all action on the handle is stopped. The latest generation of GOLIATH safety brakes (internal, permanent and independent from the handle) (For more information) of the TPV,TA and TS winches offer constant safety, including when the handle is removed (prevents unauthorised access to the winch).

Pulling on an inclined plane: Pulling on an inclined plane is a lifting operation

Whether the load is self-supported or not, the force, and so the winch capacity, can significantly vary (from 1 to 5 depending on the case). The load capacity we provide in our datasheets for this type of application takes into consideration a slope of 20% and friction coefficients corresponding to those of a vehicle equipped with bearings.

Force on the handle: 12 kg maximum recommended

Quality winches designed in compliance with the European standard EN13157 A1, are provided for a maximum load capacity with a force on the handle that cannot exceed 25 kg first layer and last layer load).

This is a rated capacity and not a capacity of use. In general, one considers that a 12 kg force on the handle is acceptable. To obtain this maximum force level, the load on the winch should be limited to approximately 50% of its rated value.

Please note that the latest generation of TPV-TA winches are equipped with 2 reduction axes making it possible, according to uses, to divide the force on the handle by 2. See the new generation of TA-TPV winches

Capacity: The wound cable length has an impact on the winch capacity

The load capacity of the winch (100% force applied directly to the cable) depends on the cable winding level on the drum. In fact, the mechanical force transmited by the cable to the winch proportionally increases with the winding of the latter on the drum. In other words, the more the load is lifted, the more the transmitted force is significant, thereby reducing the capacity of the winch. For this reason, the standard considers a first layer and a last layer load:

- 1st layer (drum pitch diameter diagram)

The first layer is the minimum filling level of the drum. The load capacity of the winch given for a 25 kg force on the handle is then maximum, but is not a use value, as the winch cannot be used with this load (lifting/winding capacity equal to 0).

- Last layer (full drum diagram)

The maximum last layer load value, still for a 25 kg force on the handle, is the maximum capacity of the winch if the cable is completely wound on the drum.

Consequently, the winch capacity will depend on the cable length wound on the winch when the load is lifted to the maximum. To optimise this value and select the winch best suited for the application, it is necessary to limit the cable length wound on the drum to strictly: lifting height + 1 metre (minimum safety winding on the drum). Our Goliath Store configurator allows you to carry out simulations and indicates the references best suited for your application.For more information

Cables: Adhere to the recommended diameters

Each winch is determined according to a cable diameter adapted to its capacity. It is then recommended for optimum use of the winch to use the corresponding cable. A cable with a close diameter can eventually be used. WARNING! In this case, the winch capacity will eventually be reduced proportionally to the difference in breaking capacity of the cable.

Protective cover: Compulsory to be compliant with the EC standard and for your safety

It is imperative that the winch be equipped with a protective cover preventing access to the mechanism in order to avoid any accident.

- Original ref. : 954903

- Unit weight : 22.38 Kg

- Builder : AIN, RSA

- Pulling capacity : 3000kg

- Number of speeds : 2

- Reduction ratio 1 : 1/10

- Reduction ratio 2 : 1/21.77

- Drum hub ø : 27mm

- Strap length : 13m

- Handle length (mm) : 290mm

- Handle : Removable

La norme EN13157 A1 définit les critères essentiels requis pour assurer votre sécurité et permettre l’application du sigle CE sur les treuils (dans le cadre d’un usage Européen).

Attention ! L’apposition du sigle CE peut-être liée à une auto-certification de l’importateur ou du fabricant, ce qui conduit malheureusement à un usage abusif de son utilisation et donc de la conformité CE des produits. Soyez vigilant.

Un treuil non conforme à la norme EN13157 A1 n'est pas CE, rendant ainsi le dispositif de levage non conforme aux dispositions de la directive sur la sécurité des machines qui engage votre responsabilité.

Vous trouverez ci-dessous quelques critères indispensables requis pour la qualification CE d’un treuil. Bien entendu, la qualification d’un treuil ne saurait se résumer à ces quelques éléments. Notre objectif est ici de permettre l’identification visuelle des éléments clès de conformité à la norme :

- Auto frein de sécurité: L'auto-frein est obligatoire pour toute application de levage : Pour rappel, la norme EN13157 A1 définit le levage comme un changement de hauteur pendant le mouvement. Cela peut intégrer des mouvements verticaux ou verticaux et horizontaux de la charge ainsi que toutes les combinaisons.

- Manivelle : Elle ne doit pas être amovible, ou démontable sans outils, si l’auto-frein est partiellement, ou totalement, désactivé lorsqu’elle n’est pas en position. Sauf si le treuil dispose d’un système d’activation automatique de l’auto-frein, garantissant la sécurité des usagers.

- Carter de protection : Les pignons internes et externes ainsi que les éléments saillants du système (par exemple le tambour) doivent être protégés.

- Tambour : Le diamètre du moyeu du tambour varie en fonction du câble et mesure, suivant les cas, entre 35mm et 72mm (pour les treuils manuels jusque 1000 kg). A défaut la fibre du cable peut être endomagée et peut conduire à la rupture de celui-ci. De plus, le moyeu du tambour doit résister à l’écrasement.

- Sécurisation du câble ou de la sangle : L’ancrage du câble ou de la sangle sur le treuil doit être normalisée et résister à 3 fois la charge nominale.

- Sangles et câbles : Ils doivent être conformes à la normalisation européenne en vigueur. Attention aux sangles trop fragiles! Endomagées, leur rupture aura des conséquences parfois dramatiques.

Need A Custom Solution?

With 40+ years of manufacturing innovation, we're ready to develop products to your exact specifications. Let's create the perfect solution for you.

Request a quotation